How Do They Build Bridges In Water

As man beings started to expand beyond lands and territories, we needed a structure to overcome natural barriers and obstacles. Engineers harnessed their resources to create bridges, linking us between cities and changing the unabridged landscape.

How are bridges built? Bridge construction has undergone an immense transformation since the first of time, including new sturdier materials, heavy machinery and new construction techniques. Although building bridges is much easier in modernistic times, bridge engineering involves precise physics, vast resources and thorough planning prior to and during construction.

While bridges crave precise and careful work, the basic fundamentals of bridge construction are unproblematic one time broken down. Read on or skip to the infographic below to learn more well-nigh the nuts of span building.

Bridge Construction Process

Most bridge construction projects use a like timeline, commencement with the planning stage and ending with final testing and inspections. While larger projects may crave specialized processes, most projects follow these five steps:

Step 1: Site Inspection and Planning

Before construction begins, planners must exam the site for soil force, depth, land layout and other elements. Using computer-aided design, engineers can picture the bridge'south behavior nether unlike weights and weather atmospheric condition and determine the right construction.

Step 2: Setting the Foundation

Afterwards planning is complete, workers intermission ground on the task site and begin installing the bridge'south foundation. To do this, builders choose a stable location or drive supporting piles into the ground and install solid pillars that will later back up the remainder of the bridge. These pillars are typically fabricated out of concrete and can support immense amounts of weight.

Step 3: Installing Piers and Bridge Supports

One time the bottoms of the bridge piers are in place, crews build upward until each pier has reached its predetermined height. Depending on the size and type of bridge, supports tin consist entirely of concrete or apply a combination of steel or other materials.

Step iv: Adding the Superstructure

The superstructure includes all components that direct receive the load, including cables, support beams and latticework. To install the superstructure, engineers must harness various materials and assemble structures that maintain support when exposed to air current, gravity and other natural forces.

Step v: Last Quality and Safety Inspections

Once construction is complete, crews perform safety tests using cranes and bridge booms to ensure that the structure meets all quality standards. These tests allow engineers to rule out or accost any structural flaws and move forward with installing concluding paving and electrical systems.

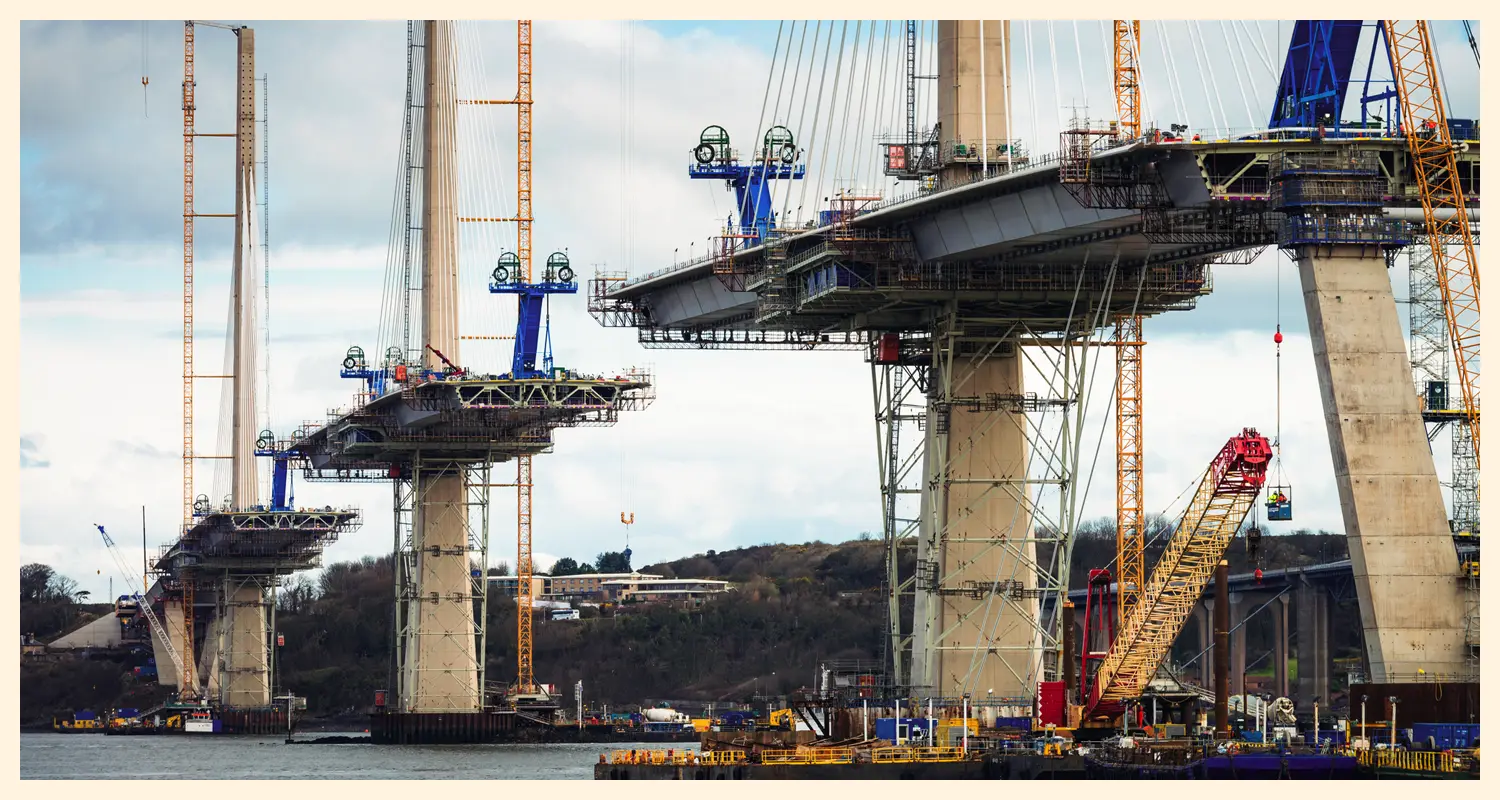

How Are Bridges Built Over Water?

Bridges congenital over h2o employ the same construction process as whatever other bridge, but there are a few extra factors to consider during the planning and construction phases.

For most bridges built over deep water, construction crews must build cofferdams or lower caissons into the water to create a dam and platform for the physical towers to stand on. Lakes and riverbeds can be unstable, so crews may need to drive piles deep into the globe to achieve stability.

If a stretch of h2o is broad enough, bridge builders may need to bring in specialized structure equipment like floating cranes, span booms and hydro platforms capable of operating over water. These machines allow workers to perform safety inspections and piece of work in areas that they can't access from the ground.

Bridge Designs

Bridges are designed to handle tension and compression in a variety of ways depending on their use and location. The most common bridge designs include:

- Suspension bridges: Cables hung from vertical suspenders support the bridge deck while piers remainder compression.

- Truss bridges: The superstructure consists of diagonal chords or beams that behave tension and compression throughout the structure.

- Curvation bridges: A steel, stone or physical arch balances compression and serves every bit a wind bracer.

- Cantilever bridges: Cantilever bridges utilise sets of upper chords to conduct tension and lower chords to handle compression.

Engineers invest a lot of fourth dimension and resources in constructing a bridge that achieves its purpose, facing like challenges as those attempting to build underwater. Although there are different types of bridges, they all employ engineering principles to act as standing structures that people use every mean solar day for transporting and commuting. Bridges are both functional in their purpose and elegant in design, reflecting the harmony engineers and builders strive to attain.

For more information on how bridges work and the structure process, check out the infographic below.

Sources:

Concern Insider | Engineering Insider | Explain That Stuff | Britannica | MadeHow | How Stuff Works | Engineering Feed | PDH Bridges | Bright Hub Engineering

Related Posts

How Do They Build Bridges In Water,

Source: https://www.bigrentz.com/blog/how-are-bridges-built

Posted by: barkleymidess.blogspot.com

0 Response to "How Do They Build Bridges In Water"

Post a Comment